Product Categories

-

- RTV-2 Liquid Silicone Rubber (22)

- Liquid Polyurethane Rubber (8)

- Electronic Potting Silicone (6)

- Clear Epoxy Resin (3)

- Silicone Fluids (3)

- Other Products (7)

- Silicone Putty (3)

- Silicone Sex Dolls (2)

Contact Details

-

- Email : info@mcsilicone.com

- Phone : 86-769-82693920

- Fax : 86-769-82606808

- Address : No.3, Chuang Ye 2nd Rd., He Lu Industrial Zone, Huang Jiang, Dong Guan, GuangDong

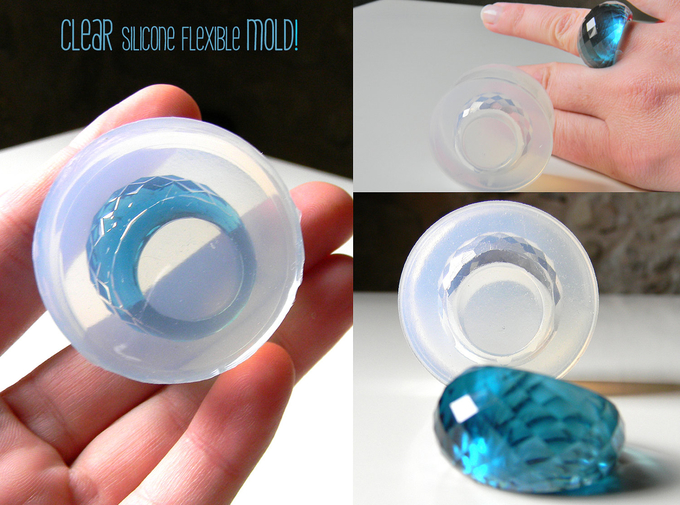

Transparent Liquid Platinum Cure Silicone Rubber for Rapid Prototyping & Jewelry Mold

-

Transparent Liquid Platinum Cure Silicone Rubber for Rapid Prototyping & Jewelry Mold

Brand Name MC SILICONE Product Origin Dongguan China Delivery Time 3-5 working days after payment Supply Ability 4 Tons per day Product Description

Description

RTV2 silicone is a two component elastomer cross-linking at room temperature. The polymerization can be accelerated by heat (max.1500 C). The silicone components are delivered as liquids, which once mixed and cured transform into a transparent, elastic and resistant material. Polymerization occurs without formation of heat.

Features

High Transparency

High tear and tensile strength

Long shelf life with low shrinkage

Fast mixing (10:1)

Easy processing due to the low viscosity

Applications

Label manufacturing, Molding applications requiring low shrinkage e.g., jewelry, automotive, plaster, cement, cake decorations, etc.

Technical Data

Product Name

Apper-ance

Shore A Hardness

Mixing ratio

Mixed Viscosity

Tensile Strength

Tear Strength

Elongation

Shrinkage

MCPLA-H35

Clear

35

10:1

30000 cps

≥4.5 MPa

18N/mm

350%

<0.1

MCPLA-H40

Clear

40

10:1

40000 cps

≥6.0 MPa

27N/mm

350%

<0.1

MCPLA-H50

Clear

50

10:1

40000 cps

≥5.8 MPa

25 N/mm

350%

<0.1

Curing time

Product name

Pot life(25℃/h )

Curing time (25℃/h )

60℃/h by heating

200℃/h by heating

MCPLA-H35

1 hour

12 hours

2 hours

5 mins

MCPLA-H40

1 hour

12 hours

2 hours

2 mins

MCPLA-H50

1 hour

10 hours

2 hours

10 mins

Processing and Instructions of Addition Cure Silicones

1. Mixing the two components

According the mixing ration 10:1 or 1:1 weighting A and B, the two components may be thoroughly mixed either by hand or using a low-speed electric to minimize the degassing of bubbles and to avoid any temperature increase. Note: It is also possible to use a special mixing and dispensing machine for the silicone components, further information is available upon request.

2. Moulding

The mixture should be degassed preferably at 30 to 50 mbar to eliminate any entrapped air. If a dispensing machine is used, the two components are degassed separately prior to mixing. The silicone mixture expands to 3-4 times of its initial volume and bubbles rise to the surface. The bubbles progressively disappear and the mixture returns to its initial volume after 5 to 10 minutes. Wait a few minutes to complete the degassing and then flash the vacuum. The silicone is ready for pouring, either by gravity or under low pressure.

Note: Flashing the vacuum once or twice accelerates the degassing. It is recommended to use a container with a high diameter/height ratio (3 to 4 times of the initial volume)

3. Polymerisation

The curing may be slowed down at lower temperature or accelerated by applying heat.

Note: in general contact with certain materials can inhibit the cross linking of RTV.

Natural rubbers vulcanized with sulfur

RTV silicone compound catalyzed with metal salts, e.g. Tin compounds PVC stabilized with tin salts and additives

Epoxy catalyzed with amines

Certain organic solvents, e.g. Ketones, alcohols, ether etc.

Important

The platinum catalyst is contained in component B.Caution

Only components A and B that have the same lot number may be processed together!

To ensure both optimum flow and homogeneity of the material, the components must be stirred thoroughly before they are removed or processed in their containers, in order to uniformly disperse any fillers that might have settled during storage.Packaging

Part A: 20kg/drum Part B: 1 kg/drum

Special containers are available are on request.

Storage & Shelf life

When the silicone rubber is stored at or below 30 centi degree in the original unopened containers, Silicone Base and Curing agent have a usable life of 10 months from the date of production. After 10 months stockpiles use the Stir to mix the Part A silicone for some minutes, then the silicone can be use again, no influence for other performance.